'Internet Plus' empowers China's manufacturing

- By Zhang Jingwei

0 Comment(s)

0 Comment(s) Print

Print E-mail China.org.cn, January 16, 2016

E-mail China.org.cn, January 16, 2016

|

|

|

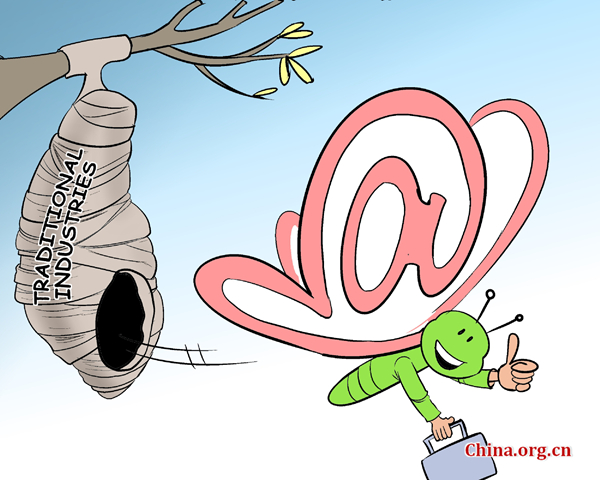

Cocoon into butterfly [By Jiao Haiyang/China.org.cn] |

Years ago, floods of entrepreneurs swarmed to the coastal areas in southeast China, the frontier of the country's reform and opening up, and gained huge fortunes. But today, they are looking to developing countries in Southeast Asia where the cost of production is lower.

Entrepreneurs' first rush to the southeast coast significantly drove China's manufacturing forward, with the coastal region, especially the Pearl River Delta area and Yangtze River Delta area, gaining rapid economic growth. China has gradually grown to a manufacturing power since then.

As the manufacturing capacity repatriating to the developed countries, many factories in Dongguan and Panyu, two cities in the Pearl River Delta area, were shut down, and the Yangtze River Delta area is facing overcapacity, weak demand, price falling, financing difficulty, and rising labor cost.

However, within an open global market, capital flows wherever profit is possible. That means, if the costs in Southeast Asian countries get higher than that in the western markets, global manufacturing would also flow to the latter.

In fact, the Chinese government has been brewing a strategic layout to upgrade "Made in China" to "Created in China" for years. But the time-consuming industrial upgrade has had to face various challenges. The traditional processing model that is low-end, extensive, low value-added and labor intensive is reaching a dead end. China's industrial structure is no longer a favoring factor for the growth of the low-end processing model. As the demographic dividend weakens and labor price rises, the low-end manufacturing space in China is being further squeezed.

Statistics from the Economist magazine show that the average labor cost of China's manufacturing is 3.27 US dollars per hour, which is two thirds higher than that of Vietnam and a quarter higher than that of Malaysia. This proves that labor intensive processing and manufacturing industries have become unsustainable in China, and the only way out is to upgrade.

To upgrade the industries, we need to turn "Made in China" to "Created in China," which requires laborers to not only do physical work but also contribute ideas.

Go to Forum >>0 Comment(s)